Enhancing Design Stability with Motion-Based Collision Verification | CADvizor’s Latest Feature Analysis

In automotive design, collision verification is a critical step directly tied to driver’s safety. Conventional CAD software has primarily relied on static models to detect collisions, making it difficult to account for dynamic interference that may occur in real driving environments.

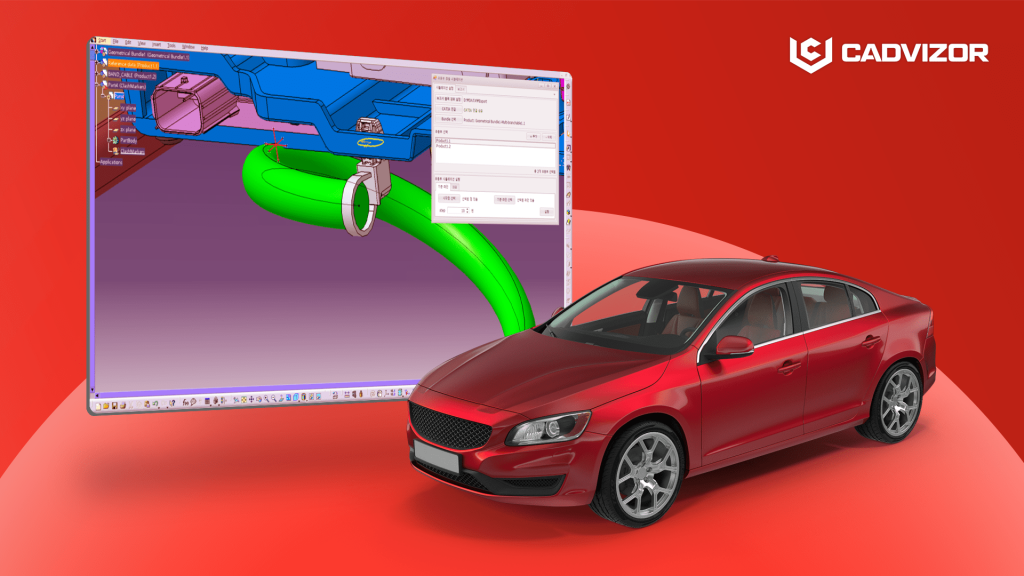

To overcome this limitation, Yura’s CADvizor, an advanced electrical design CAD solution, has introduced a new feature: motion-based collision verification (dynamic collision simulation).

CADvizor’s New Feature: Motion-Based Collision Simulation

The newly applied simulation feature goes beyond identifying static interferences between components. Instead, it incorporates the actual movement of parts within the vehicle into the verification process.

Applicable Targets: Seats, engines, transmissions, steering wheels, pedals, and other moving components

Key Advantages:

Motion Path Reflection – Visualizes part trajectories through 3D simulation

Automated Report Generation – Provides instant collision reports after design modifications

Verification Speed Improvement – Reduces verification time by up to 70% compared to traditional processes

Combined with CADvizor’s existing wiring harness design and electrical routing simulations, this function further enhances overall design stability.

Industrial Impact: Achieving Both Safety and Cost Reduction

Motion-based collision verification is more than just another validation tool—it is a transformative solution for automotive design processes.

Improved Design Stability: Prevents dynamic interference issues in advance, ensuring safety

Reduced Development Costs: Fixes errors before prototype production, minimizing unnecessary builds

Shorter Lead Times: Automates verification and reporting, reducing project schedules by over 30%

Scalability: Applicable not only to automotive design but also to aerospace, shipbuilding, and heavy equipment industries

According to reports, a global automaker applied CADvizor’s new feature and was able to detect a seat sliding rail collision issue at an early design stage. This enabled the company to expect cost savings in prototype production and significant reductions in documentation time for verification.

CADvizor’s motion-based collision verification goes beyond the limitations of static CAD validation, delivering dynamic simulation for enhanced design reliability.

This innovative feature is expected to help industries achieve three major values simultaneously: safety, cost reduction, and faster development cycles. CADvizor continues to position itself as a pioneering platform in electrical CAD design and verification, setting new standards for the future of automotive engineering.