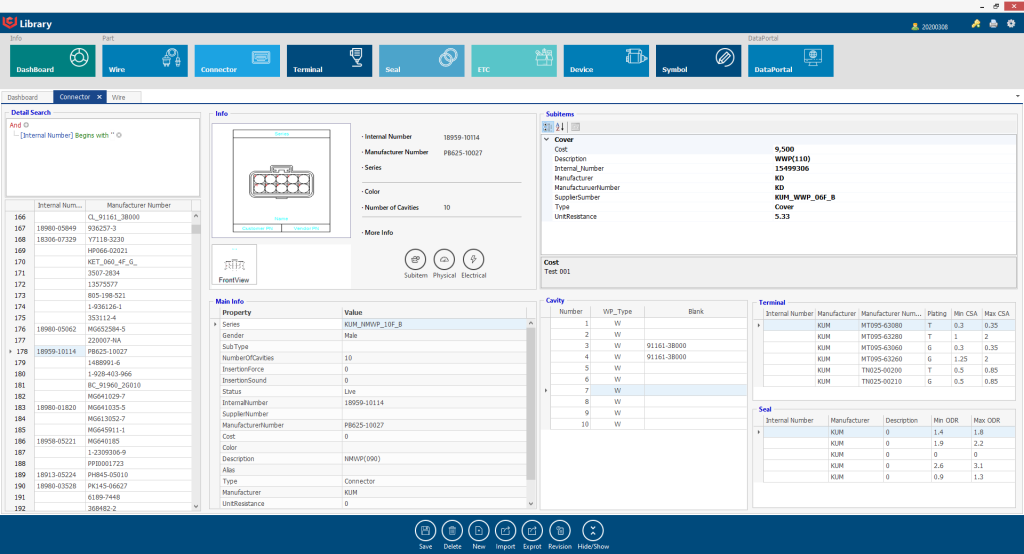

Concurrent Engineering

Concurrent engineering is a systematic method of designing and developing products where different activities run simultaneously. This is also known as simultaneous engineering. By performing different tasks simultaneously, concurrent engineering decreases the production time leading to reduced costs. Although concurrent design and manufacturing requires extensive communication and coordination between disciplines, the benefits can increase the profit of a business and lead to a sustainable environment for product development. Concurrent design and manufacturing can lead to a competitive advantage over other businesses as the product maybe produced and marketed in less time.

Sequential Engineering

In contrast, sequential engineering begins with customer requirements and then progresses to design, implementation, verification and maintenance. The approach for sequential engineering results in large amounts of time devoted to product development. Due to large amounts of time allocated towards all stages of product development, sequential engineering is associated with high cost and is less efficient as products cannot be made quickly.

Expected Benefits(Concurrent Engineering)

– Less material wasted

– Allows for early correction of part

– Large amount of same part produced in shorter amount of time

– Ability to leverage teamwork and make informed decisions

– Better communication between disciplines in company

<Concurrent Engineering vs Normal Engineering>

Examples of Concurrent Engineering

Image on the right side illustrates companies which have adopted the concept of ‘Concurrent Engineering’ in operation. These companies have significantly reduced the time it takes to go from idea to product. Reducing or eliminating extra steps means the products made from these organizations have been completed sooner with less wasted material in the process. In addition, during the design and prototyping process, potential issues in the design have been corrected earlier in the product development stages to further reduce the production timeframe.

<Organizations which adopted

concurrent engineering>

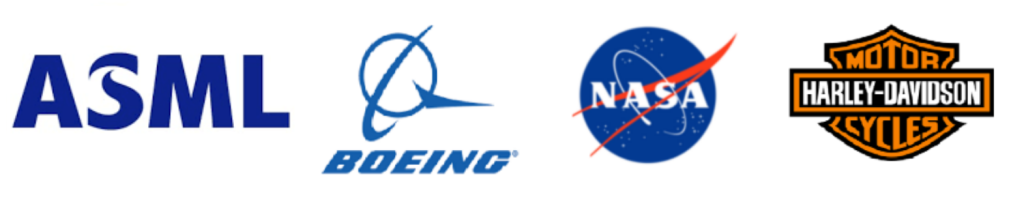

Collaboration through Concurrent Engineering

Concurrent engineering encourages multidisciplinary collaboration. By having several teams working simultaneously, this method increases productivity, reduces the time and the costs of the product cycle and allows for streamlining of all product development processes. So how do we align team members’ goals to the product? The answer for this is simple. We need to encourage extensive level of information exchange to each other through a certain CAD platform. Information exchange and cooperation can be accelerated through implementation of ‘concurrent engineering’ approach.

Concurrent Engineering Architecture

Cloud-based CAD will enable professionals from diverse functions to work collaboratively as data is updated in real-time. Hence, workers can work together on the latest version of electrical drawings. CADvizor provides opportunity for cost engineers to utilize ‘Cost simulation function’, R&D specialists to utilize ‘Topology simulation function’, and other related parties to utilize ‘libraries, BOM(bill of materials) and design viewer’. Hence, competitive CAD solutions enable the concept of ‘concurrent engineering’ to be applied and implemented adequately.

<CADvizor Architecture>

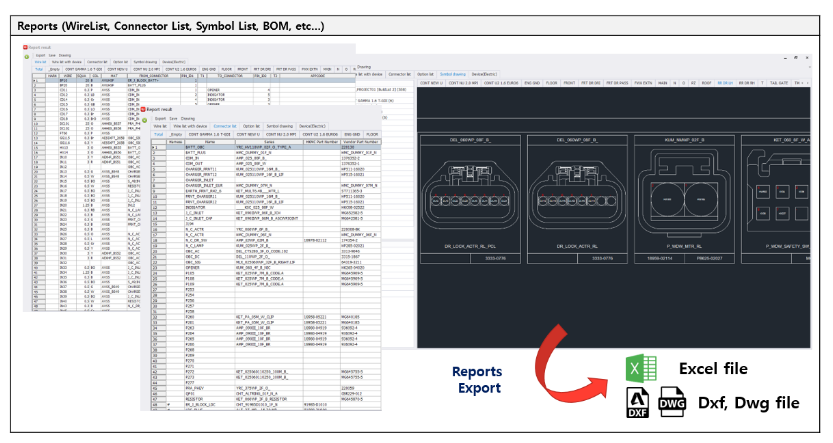

<CADvizor Bill of materials & Report>

Cost Simulation

Implementing ‘concurrent engineering concept’ is quite difficult when using traditional CAD. This is because electrical designers need to manually draw electrical circuits. Each data entry cannot be automated which means BOM(Bill of materials) information is not instantly available for all functional parties. CADvizor provides ‘Cost simulation feature’ where electrical designers could see how much each automotive component would cost in certain electrical design settings.

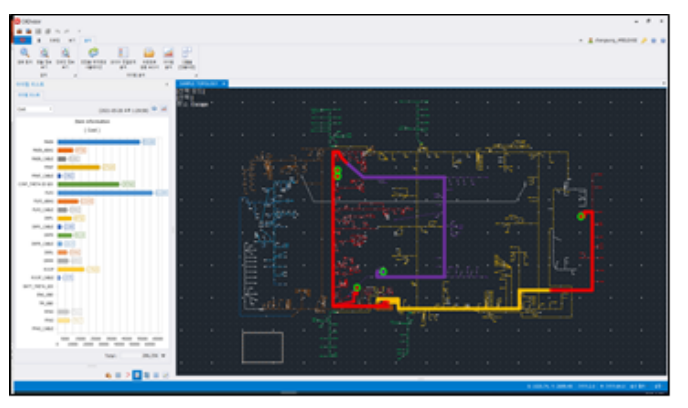

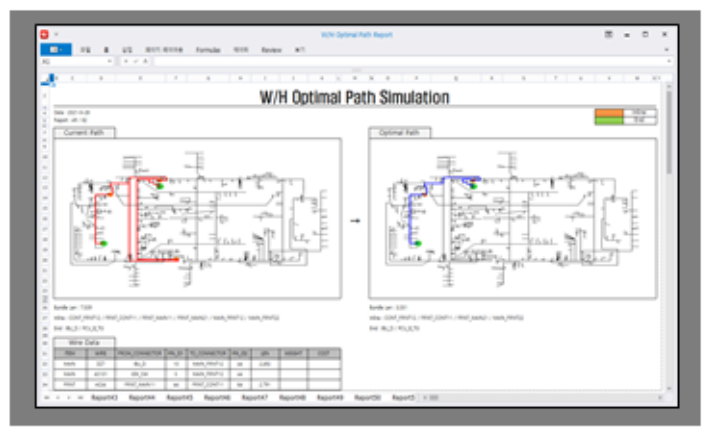

Topology Simulation

CADvizor offers topology simulation feature where engineers can streamline the route for electrical component design. A set of recommended paths which connect two different electrical device are recommended. Electrical engineers can then select the most optimal path after thoroughly analyzing and comparing a set of recommended paths. At the same time, engineers could switch the position of each electrical device and evaluate if the specs of electrical components could be further optimized. Clients who have used our topology feature have experienced significantly improved quality of products.

<Cost Simulation>

<Topology Simulation>

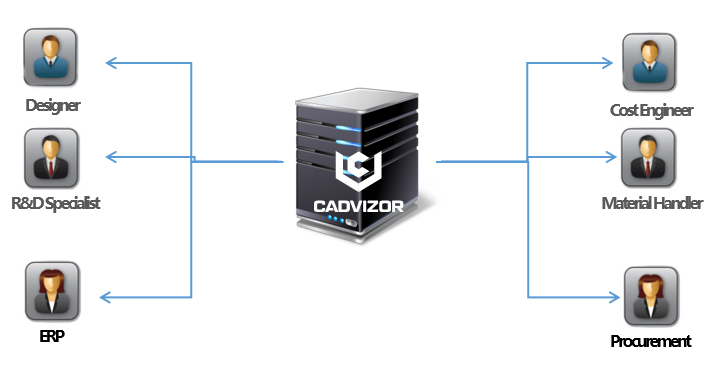

Library

Libraries are powerful and flexible tools that electrical engineers use to manage specifications of common materials, objects, or components. Industry leading CAD solution providers tend to provide a set of libraries to assist engineers develop sophisticated level of electrical design. In order to deliver high quality electrical products with minimal cost, electrical engineers should be able to select the optimal spec of electrical components such as wires, terminals, connectors, seal etc.

CADvizor provides 2 million units of libraries and this is updated weekly. Viable options of wires, terminals, connectors and seals are listed in each specific electrical design settings. ‘CADvizor Libraries’ are shared with electrical engineers, and other related parties including cost engineers, material handlers, and ERP professionals. These shared data enables workers to collaboratively work together to come up with competitive electrical products.