Increase in Automotive Component Recall Cases; Tips for Wiring harness designers

2020 Recall Annual Report; What does it represent

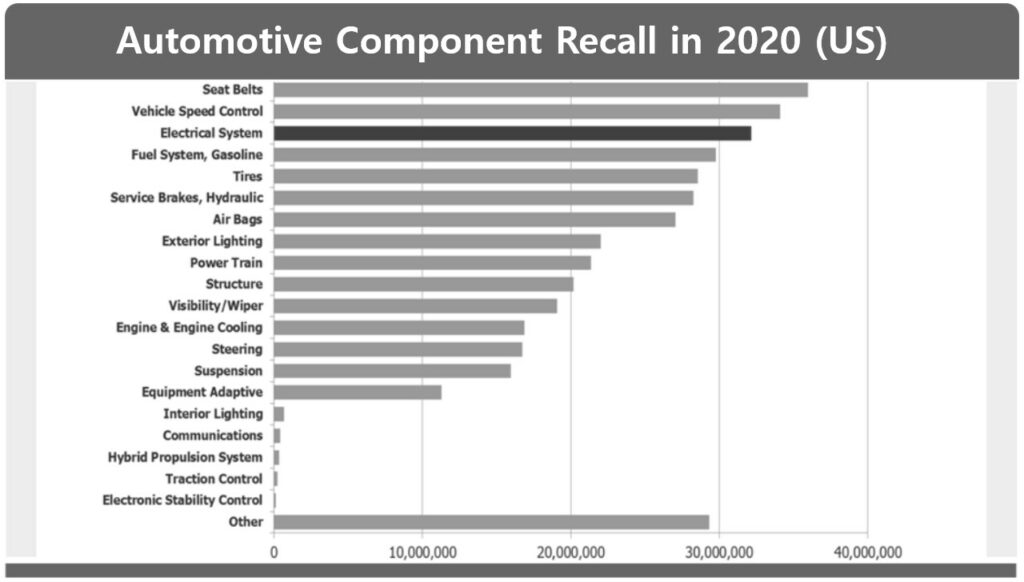

‘2020 Recall Annual Report’ published from NHTSA, illustrates how many product recall cases has been occurred from each automotive component. ‘Seat belt’ is the item with the highest product recall cases. Most importantly, ‘Electrical system’ ranks the 3rd, indicating that it is also one of the most frequently recalled automotive components in the United States. In addition, other vehicle components such as ‘Fuel system, Gasoline’, ‘Tires’, ‘Power Train’ also recorded significant number of recall cases in 2020.

Increase in cost due to complexity in electrical design

Complexity in electrical design makes it difficult for electrical designers to accurately and precisely design blueprints. This commonly causes problems such as 1) product defects and recall 2) Delays in production 3) Need to purchase expensive CAD software. As a result, sophisticated level of electrical design is commonly required. In other words, Companies’ competitive advantage is determined by the capability to come up with diverse range of models with numerous electrical options.

Product Defects cause severe problems

There are numerous cases of fire accidents related with electric Vehicle. Cases are associated with excess current, damage of cables and copper wires, etc. Other frequently occurred problems also include intermittent failures of vehicles, breakdown of clutch and error from onboard computer memories. In the US, a fatal crash of an electric vehicle involved intense fire where the vehicle’s lithium-ion battery case was damaged.

How to sustain 'Competitive Advantage'

To sum up, various types of production related issues could occur. Majority of industry leading automotive manufacturers are preparing for the era of electric vehicles. In order to sustain competitive advantage in the long term, it is recommended that automotive manufacturers strive for coming up with consistent level of high quality vehicles, and minimize the cases of product recalls. Implementation of ‘Model-based systems engineering’ enables electrical designers to design electronic blueprints efficiently.