CADvizor CADvizor: Designing ESG Competitiveness Through Energy Efficiency 2025-10-29 Across global industries, carbon reduction and energy efficiency have become key pillars of […]

Blog: Your Hub for Electrical Design Expertise

CADvizor CADvizor | Data-Driven Electrical Design for the Era of Complexity 2025-10-29 As digital transformation accelerates, electrical and electronic systems are becoming […]

CADvizor Electrical Circuit Simulation | Ensuring Design Reliability with Voltage Drop & Overcurrent Verification

CADvizor CADvizor Electrical Circuit Simulation | Ensuring Design Reliability with Voltage Drop & Overcurrent Verification 2025-10-28 Electrical harness design in industries like […]

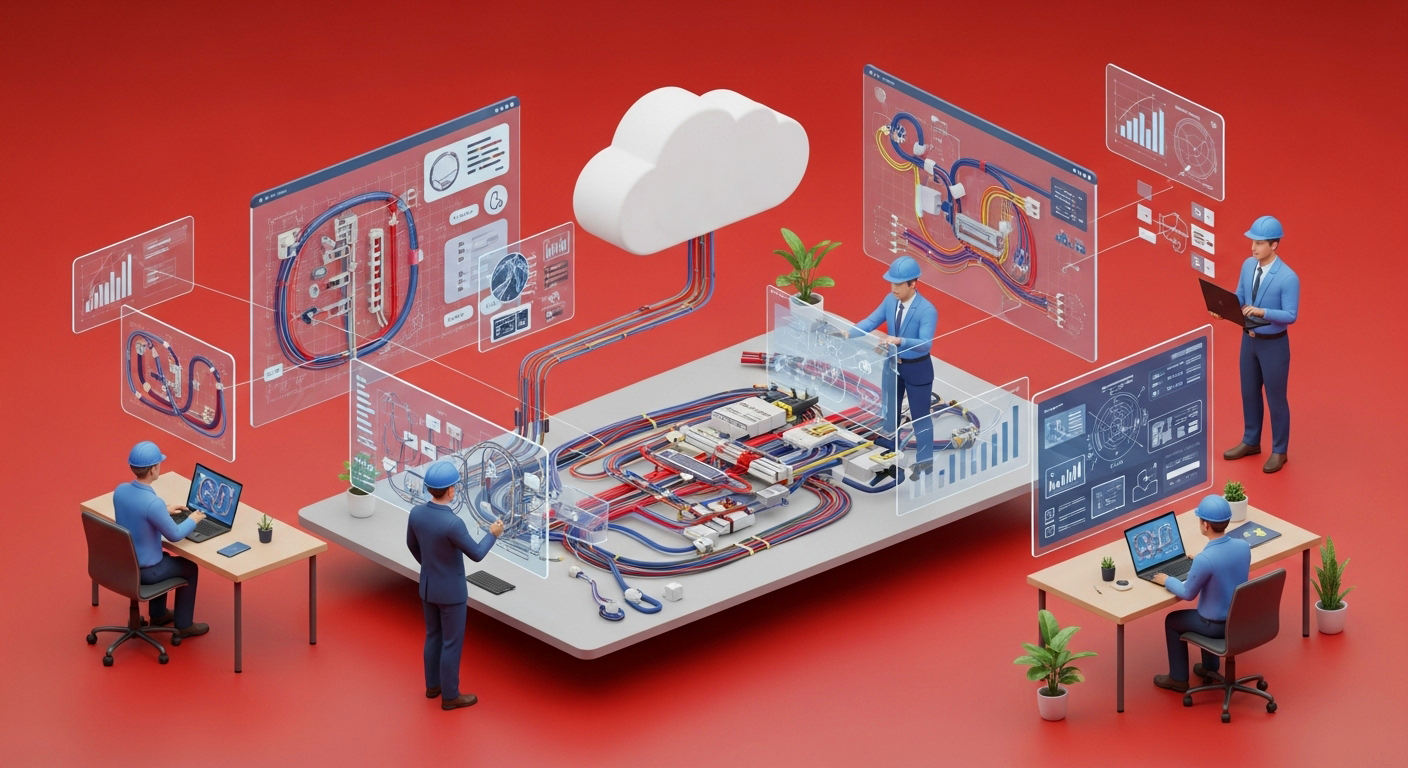

CADvizor Opening the Future of Electrical Design with CADvizor Cloud CAD 2025-10-28 Electrical system design is no longer confined to a single […]

Next-Generation Electrical Design Platform for Aerospace | CADvizor’s Cloud and AI Automation Revolution

In the aerospace industry, even a single design error can lead to massive cost overruns and project delays, as managing complex aircraft wiring harnesses and extensive electrical systems demands an extraordinary level of precision and efficiency.

Why is CADvizor Essential for Wiring Harness Design?

In industries such as automotive, aerospace, industrial machinery, and electronics, almost every complex system includes a wiring harness — a structured bundle of wires responsible for transmitting power and signals.

As electrical and electronic systems become increasingly sophisticated and design complexity rises, the design environment across automotive, aerospace, and industrial equipment manufacturing is rapidly changing.