Tips on how to implement ‘Model-based engineering’ approach

DOCUMENT CENTRIC ENGINEERING

Market players in the automotive industry are preparing for the era of ‘electric vehicles’. Customers’ expectations are evolving accordingly, hence companies must be able to capture unmet needs and provide approrpriate solutions to customers in the long term. In traditional automotive industry, there is certain degree of deficiencies which are posing threats for companies’ profitability, innovation and growth. The extreme complexity of the process and data management present a need for higher levels of transparency, agility and compliance.

Some organizations take ‘document-based approach’ where many documents are generated by different authors. In traditional design process, design information is transferred and handled in the form of text-based documents, which are difficult to understand and subject to interpretation bias. Engineers create data manually from text-based documents, leading to a time consuming and error-prone process.

MODEL-BASED ENGINEERING

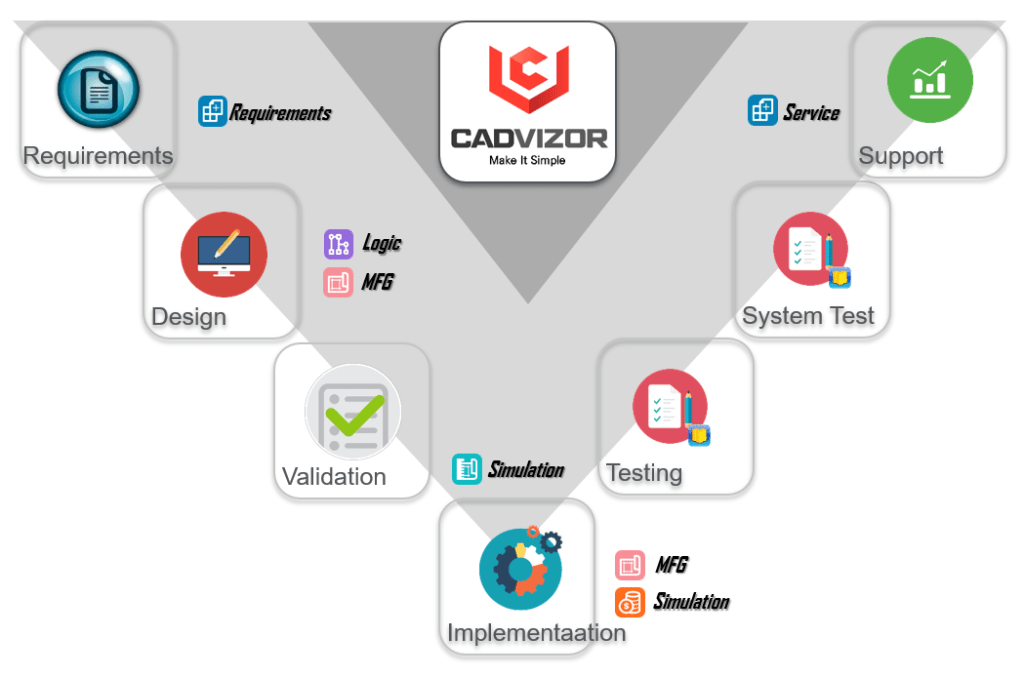

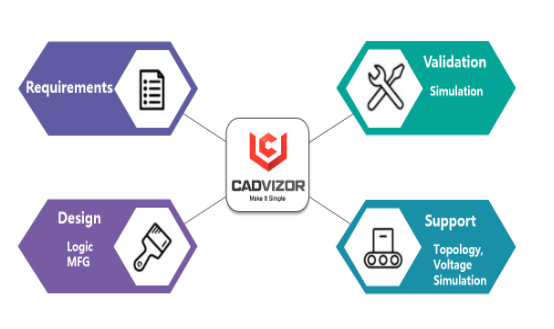

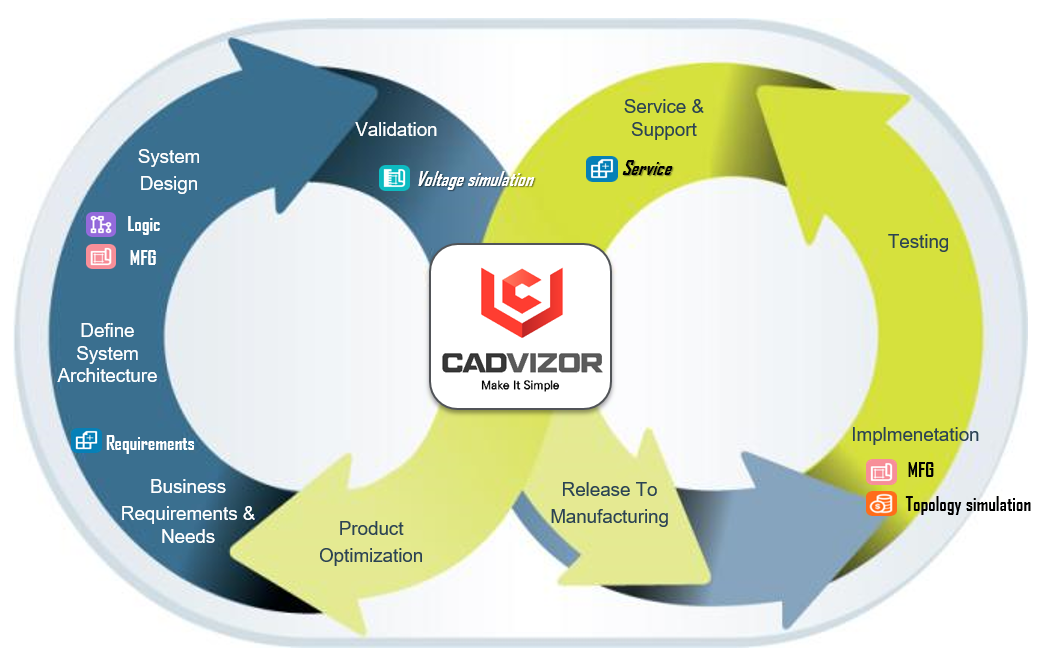

Model-based engineering is a formalized methodology that is used to support the requirements, design, analysis, verification, and validation associated with the development of complex systems. In contrast to document-centric engineering, model based engineering puts models at the center of system design. ‘Model-based engineering’ provides a single design platform to optimize overall system design. ‘Model-based engineering’ can be effectively integrated into a development process, but organization must commit effort on establishing it.

According to research from Kearney’s automotive software benchmark index, expected benefits of ‘model-based engineering’ include 20 to 30 percent reduction in time to market by enabling continuous integration and testing. Also, collaborative teamwork and model reuse allows 10 to 20 percent reduction in development costs. To summarize, Model-based engineering provides a means to coordinate system design activity, satisfies stakeholder requirements and provides a significant return on investment.

BENEFITS OF MODEL-BASED ENGINEERING

- Time to market reduction for new product development cycles

- Handling sophisticated embedded systems with expanded capacity

- Faster iteration without any need for major hardware changes

- Reduced number of prototypes, leading to higher ROI

- Controlled design, analysis, and constant testing for improvement

WHY ORGANIZATIONS SHOULD IMPLEMENT 'MODEL-BASED ENGINEERING' APPROACH

- Enhanced communication across the lifecycle

Using model based engineering supports internal communication. Having all relevant product data in a shared model enhances knowledge transfer between all stakeholders involved in development. - More confidence in changing the system

Using model-based engineering allows flexibility. Workers can add or modify requirements any time without deteriorating the product’s standards of safety. It also helps remove ambiguity, and improve the precision of system designs. - Verifying product quality, supporting compliance

By generating code automatically based on the model, risks involved in delivering code for complex software systems is reduced. Taking a model-based approach is expected to result in 30% faster delivery, and 50% less errors.

TIPS ON HOW TO PREPARE FOR 'MODEL-BASED ENGINEERING APPROACH'

- Evolve to more model-based system

Manufacturers need to evolve to more model based and systems focused work practices across their engineering domains. This will open unbounded opportunities for reusability, simulation trade studies and support much earlier verification cycle. - Engineering teams connected within a digital enterprise

Organizations should have engineering teams connected within a digital enterprise. This means having exposure early and often to transparent and frictionless exchange of product information, providing traceable evidence from concept on through the whole product maturity lifecycle. - Mindset shift away from physical to virtual.

Mindset shift from physical to virtual will allow for an exponentially greater alignment across disciplines and with management, yielding higher quality, higher confidence, increased transparency, and earlier diagnosis of issues.

SOURCE

- Automotive assembly line image, sourced from ‘New business models in the automotive industry’

- Kearney Digital/Article, ‘Marcus M.Weber’, sourced from ‘A Guide to model-based systems engineering’

- Software Engineering Institute, ‘Nataliya Shevchenko’, sourced from ‘Requirements in Model-based Systems engineering(MBSE)’

- Intland Software, ‘Using model-based engineering in system of systems development’

- Siemens Digital industries software, sourced from ‘What is model based systems engineering’