'Library Management System' for effective electrical design

Inefficient management of Data

Manufacturing companies and vehicle producers strive for reducing ‘time-to-market‘ while ensuring the competency of electrical components. Effectively designing electrical circuits is becoming a key success factor in automotive industry as well as other sectors such as robotics, heavy equipment, aviation and defense industry. Meanwhile, inefficiencies associated with repetitive electrical drawings, limited time for actual product development, intensifying customers’ requirement are key obstacles for manufacturers.

Library Management System

Manufacturers can identify root cause of repetitive electrical drawings, eliminate bottle-neck and improve productivity. However, majority of manufacturing companies face problems where workers in each department create their own libraries when working on designing components. This leads to increased cases of electrical circuit redesign, making it more difficult to secure products’ reliability. Establishing ‘Library management system’ can help resolve these issues by standardizing massive set of library data.

Standardized set of Libraries

Standardized and consistent set of electrical drawings data give flexibility for related stakeholders as they can make adjustments relatively easily. Each stakeholder can also track back history of each electrical drawings settings. Electrical drawings created from unstandardized set of libraries typically disable data synchronization. In case of failure, electrical engineers need to manually enter data per process, increasing the chance of human error.

Cooperative Approach

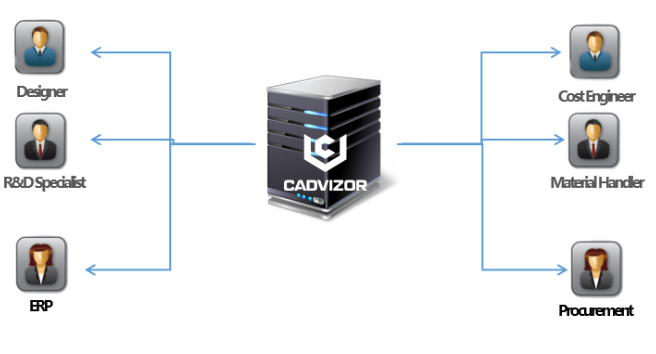

Libraries are powerful and flexible tools that electrical engineers use to manage specifications of common materials, objects, or components. Standardized set of libraries can be utilized numerous times, allowing engineers to save time and improve productivity.

Manufacturing companies tend to have established system of libraries which are shared among various departments such as procurement, ERP, R&D, cost department, etc. Library data is the fundamental data for product development.

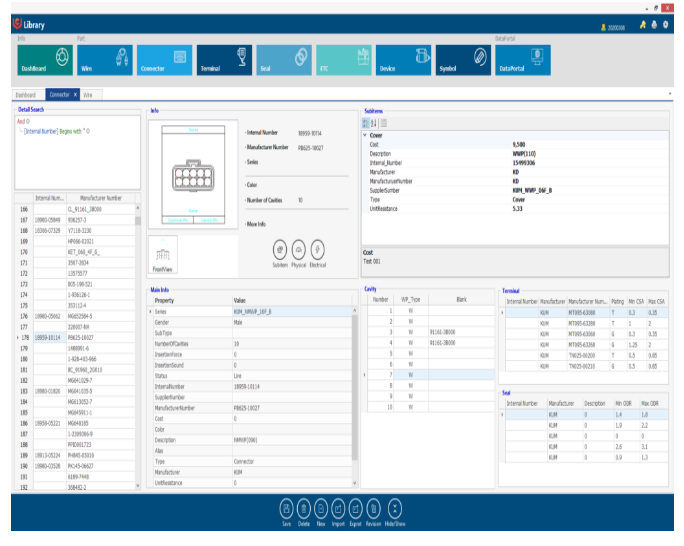

CADvizor Library - 2 Million units of Libraries

Industry leading CAD solution providers tend to provide a set of libraries to assist engineers develop sophisticated level of electrical design. In order to deliver high quality electrical products with minimal cost, electrical engineers should be able to select the optimal spec of electrical components such as wires, terminals, connectors, seal etc.

CADvizor provides 2 million units of libraries and this is regularly updated. Viable option of wires, terminals, connectors and seals are listed in each specific electrical design settings. ‘CADvizor Libraries’ are shared with electrical engineers, and other related parties including cost engineers, material handlers, and ERP professionals. These shared data enables workers to collaboratively work together to come up with competitive electrical products.

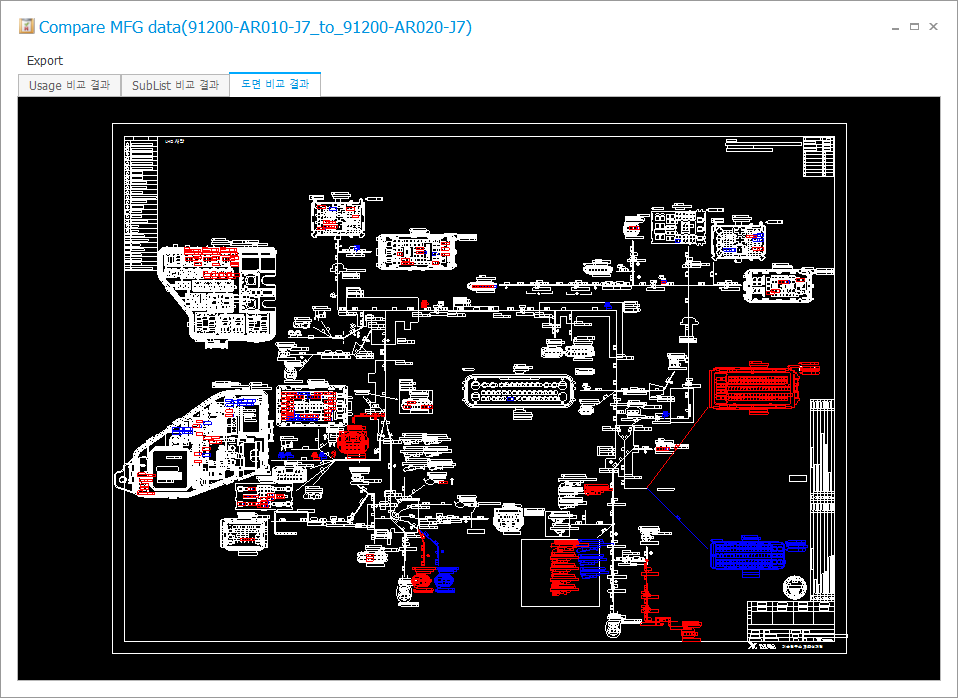

Foundation for comparing Design Data

Electrical engineers utilize CAD library resources from entire product development process from requirement to production. Specifically in development process for production, bill of material information is available in each electrical drawing settings.

CADvizor Manufacturing Design Module has function which allows electrical engineers to compare ‘Bill of material information’ between two different electrical drawing settings. Hence, related stakeholders in other departments can get idea on which item type costs more or less. Material costs, labor costs and other expenses can all be calculated by using ‘CADvizor Manufacturing Design Module’.